CVD 장비

TCVD-D100CA

Thermal Chemical Vapor Deposition

열화학증착(TCVD)기술의 주요 사항은 기판 위에 얇은 필름이 합성되는 고압의 reactor로

1,000ºC 가량의 고온에서 가스들을 유입시키는 것입니다.

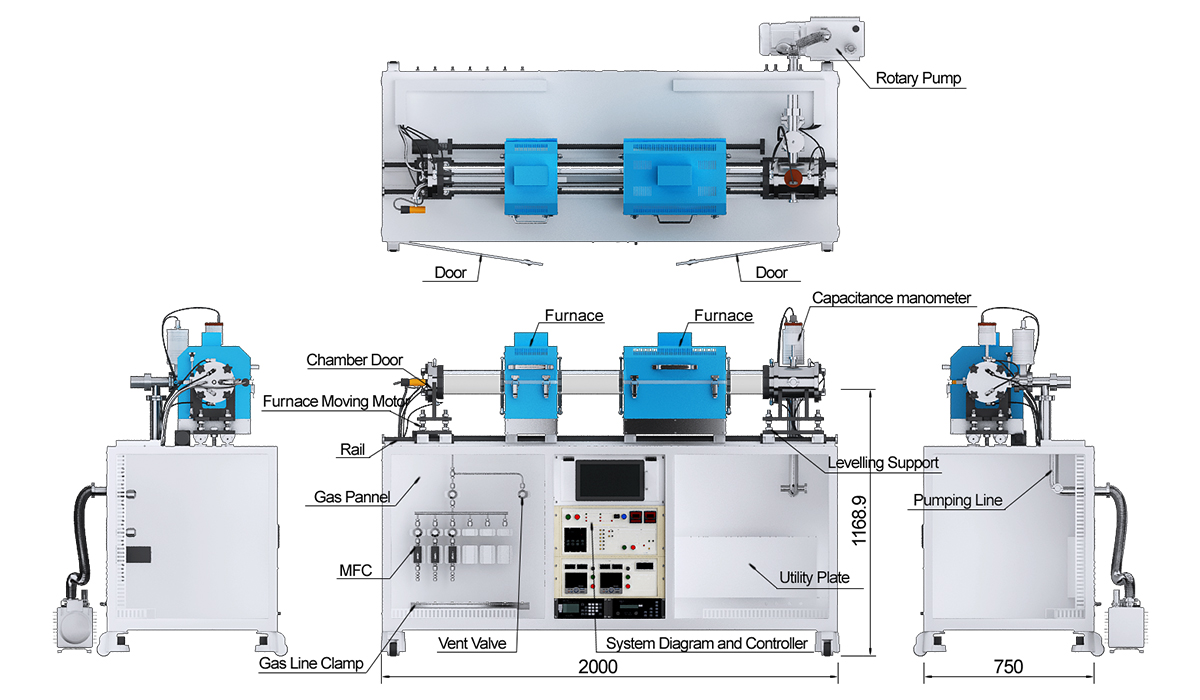

Size

2300(W) x 1770(H) x 750(D)

특징

size (mm): 2300(W) x 1770(H) x 750(D)

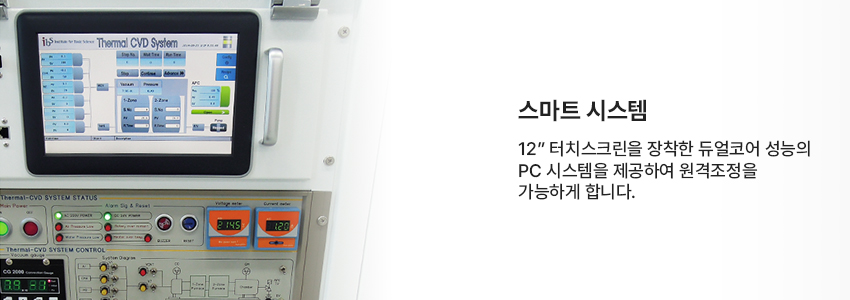

컴퓨터 제어 자동 시스템

graphene, CNT, h-BN TMDC 성장에 최적화

Water-cooled end chambers doors.

온도 조절: ~1,100 ℃

필름 두께의 균일성: ≤+-3%

테스트 균일: ≤+-3%

빠른 가열, 냉각을 위한 모터 제어 가동 히터

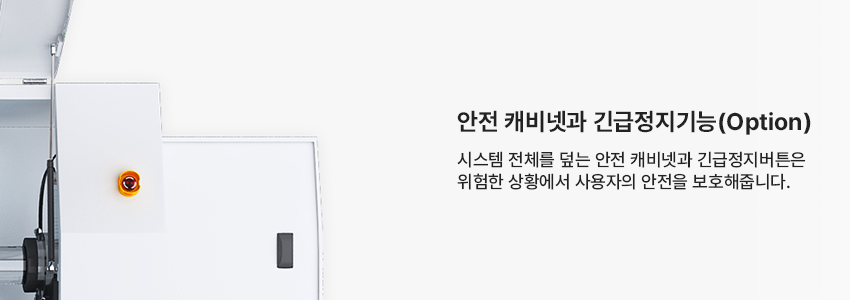

안전 캐비닛

* 가격은 상담 후 결정됩니다.

(표준 부분에서 다른 사용자 정의는 전체 가격에 영향을 미칠 것입니다.)

컴퓨터 제어 자동 시스템

graphene, CNT, h-BN TMDC 성장에 최적화

Water-cooled end chambers doors.

온도 조절: ~1,100 ℃

필름 두께의 균일성: ≤+-3%

테스트 균일: ≤+-3%

빠른 가열, 냉각을 위한 모터 제어 가동 히터

안전 캐비닛

* 가격은 상담 후 결정됩니다.

(표준 부분에서 다른 사용자 정의는 전체 가격에 영향을 미칠 것입니다.)

장점

기술사양(표준)

Thermal CVD Auto Operation system

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Down stream Auto pressure control Throttle valve

with controller

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and training

System Program ( Auto processing system)

Furnace for source evaporation

Safety interlock system(Water / Air)

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Down stream Auto pressure control Throttle valve

with controller

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and training

System Program ( Auto processing system)

Furnace for source evaporation

Safety interlock system(Water / Air)

기술사양(추가)

Max temp 1500℃ Furnace by SIC source

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addition total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Gas Safety interlock system for gas leak

RF plasma ( ICP type )

Tungsten filament gas source cracking

High Vacuum processing option

(Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addition total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Gas Safety interlock system for gas leak

RF plasma ( ICP type )

Tungsten filament gas source cracking

High Vacuum processing option

(Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

소모품

K-type Thermocouple (Option : R-type)

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

구매 고객 리스트

| 서울대 |

설계도

품질보증

그래핀 스퀘어에서는 장비를 구매하신 고객분들께 전체 부속품 (단 quartz 유리 및 고무 오링 제외)에 대한 1년 무상 워런티 서비스를 제공합니다.

기간 내에 사용하시는 장비에서 부품 이상 또는 시스템 오류 발견시 바로 연락 주시면 즉각 24시 이내에 수리기사를 파견하여 드립니다.

기간 내에 사용하시는 장비에서 부품 이상 또는 시스템 오류 발견시 바로 연락 주시면 즉각 24시 이내에 수리기사를 파견하여 드립니다.

배송 기간

제작 완료 및 검수 공정을 통과한 모든 장비는 고객님께서 지정해주신 장소로 당일배송 드립니다.

장비 구매 과정

01

견적 요청 (info@graphenesq.com)

견적 요청 및 견적서 제공

02

구매의사 확인

고객의 구매의사 확인 (고객으로부터 Purchase order 전달)

03

Invoice / Payment

Invoice 및 Payment 자료 제공

04

제작 / Training Program 제공

1차 입금 완료 시 기계 제작 돌입 및 Training Program 제공

05

장비 동작 Test / 제품포장, 발송

제작 완료 후 최종 테스트 통과 시 제품 포장 및 발송 진행

06

도착 완료

최대 4일 이내 고객 사이트에 도착 완료

문의

샘플 및 장비 관련 문의는

info@graphenesq.com

으로 부탁드립니다.