CVD Equipment

TCVD-D100CA

Thermal Chemical Vapor Deposition

The main Thermal CVD technology involves adding gases to the pressurized reactor at high temperature of about 1,000℃ where thin film is synthesized onto substrates.

Size

2300(W) x 1770(H) x 750(D)

Features

Size (mm) : 2300(W) x 1770(H) x 750(D)

Advanced Computer Controlled Automatic System

Optimized for graphene, CNT, h-BN TMDC growth

Water-cooled end chambers and doors

Process Temperature: ~1,100 ℃

Uniformity of Film Thickness : ≤+-3%

Testing Uniformity : ≤+-3%

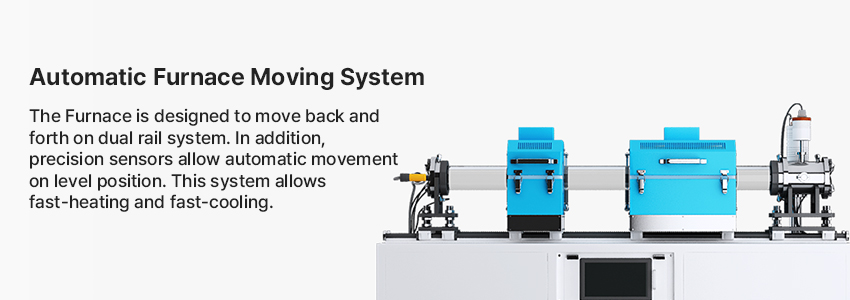

Movable furnace method is our unique knowhow for fast heating fast cooling of the sample.

* Price will be determined after consultation. (Different customization from the standard parts will affect the overall price.)

Advanced Computer Controlled Automatic System

Optimized for graphene, CNT, h-BN TMDC growth

Water-cooled end chambers and doors

Process Temperature: ~1,100 ℃

Uniformity of Film Thickness : ≤+-3%

Testing Uniformity : ≤+-3%

Movable furnace method is our unique knowhow for fast heating fast cooling of the sample.

* Price will be determined after consultation. (Different customization from the standard parts will affect the overall price.)

Advantage

Specifications

Thermal CVD Auto Operation system

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Down stream Auto pressure control Throttle valve

with controller

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and training

System Program ( Auto processing system)

Furnace for source evaporation

Safety interlock system(Water / Air)

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Down stream Auto pressure control Throttle valve

with controller

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and training

System Program ( Auto processing system)

Furnace for source evaporation

Safety interlock system(Water / Air)

Options

Max temp 1500℃ Furnace by SIC source

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addition total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Gas Safety interlock system for gas leak

RF plasma ( ICP type )

Tungsten filament gas source cracking

High Vacuum processing option

(Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addition total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Gas Safety interlock system for gas leak

RF plasma ( ICP type )

Tungsten filament gas source cracking

High Vacuum processing option

(Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

Consumable Parts

K-type Thermocouple (Option : R-type)

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

Customer List

| Seoul National University |

Layout

Quality Assurance

Graphene Square provides customers who purchase equipment with a one-year warranty on all accessories (except quartz glass and rubber O-rings).

If you find a part abnormality or system error in your equipment within the period, please contact us immediately and a repairman will be dispatched immediately within 24 hours.

If you find a part abnormality or system error in your equipment within the period, please contact us immediately and a repairman will be dispatched immediately within 24 hours.

Delivery period

All equipment that has been manufactured and inspected will be delivered on the same day to the place you have designated.

Equipment Purchase Process

01

Quotation Request (info@graphenesq.com)

Quotation Request and Quotation provided

02

Confirmation of intention to purchase

Customer's intention to purchase

(Purchase Order from Customer)

03

Invoice / Payment

Provide Invoice and Payment data

04

Provide Production • Training program

Provide machine production and training program upon completion of the first deposit

05

Equipment Operation Test /

Product packaging, Shipment

After production is completed, product packaging and shipping are carried out

06

Arrival is completed

Arrival is completed at the customer site

within up to 4 days

Inquiry

Please email to info@graphenesq.com for sample/equipment inquiries